I agree with Alan Cohen. IMHO, amps that run the tubes hard are JUNK !!! Poorly designed. If you can't get 10,000 hours out of a tube, your amp is junk. Garbage, mis-designed.

The MAIN reason people "hot rod" tubes is because they don't know how to build and properly wire an amp internally, for what "I" call maximum transfer efficiency. They use crummy ( thin ) wire, and too long of lengths ... and non-thoughtful layout choices.

To justify their mis-designs, they do an "A-B" test and guess what, the hot rodded tube sounds better on the A-B, so they think "lets push

upwards" the tubes plate dissipation ( voltage times current ).

The problem occurs as such: Within 10 hours of over-dissipation, the tube is degrading, and within 200 hours, the tube is sounding crummy compared to when it was new ( and originally A-Bed ), and maybe it will last 2,000 hours before you spend the bucks to replace them. Who the heck wants to own gear that is constantly degrading ?? Not I.

Guess what, in a properly executed amp, one that is well-wired, and has good lay out and internal wiring ( optimized for a wide -band transfer efficiency ), the "hot rodded" tube will always sound WORSE than the conservatively operated tube. Why ??

This is the way it is, in many things in nature.

The "hot rodded" tube has a higher dissipation across its plate, and as such, it is running at higher internal temperatures. In a good amp, on a good hi fi system, these high temperatures are STRESSED SOUNDING as all get out. Not "relaxed and free sounding", just stressed and uptight.

You all know these things. Your lawnmower runs better at 2/3rds throttle than at full throttle, and your family sedan runs better at 62 MPH than it does at 100 MPH. In nature, we call it "The Golden Ratio", about 62 percent as I recall.

So, say a Type 45, a pristine sounding tube - ( which KILLS KT-88s if you don't know that ) - it would be a GOOD idea to run the 10 Watt rated Type 45 at 6 or 7 Watts dissipation . It WILL easily last 10,000 to 50,000 hours, and it WILL DEFINITELY sound better at that Golden Ratio dissipation,

IF the amp is

well wired internally, and

well designed internally.

Most tube audio designers, ( or should I say the undersides of their amps - when I see them), are totally ignorant of these things I've discussed herein, or, to say it nicer, are simply unconscious of this. These amp designers are all nice fellows. I am

sure Dennis Had is a good guy, but they are lacking in the mastery of the task at hand. Running tubes hard is dumb and unjustifiable, once you understand there IS a better way to execute a tube amp.

LowOhms

- - - Updated - - -

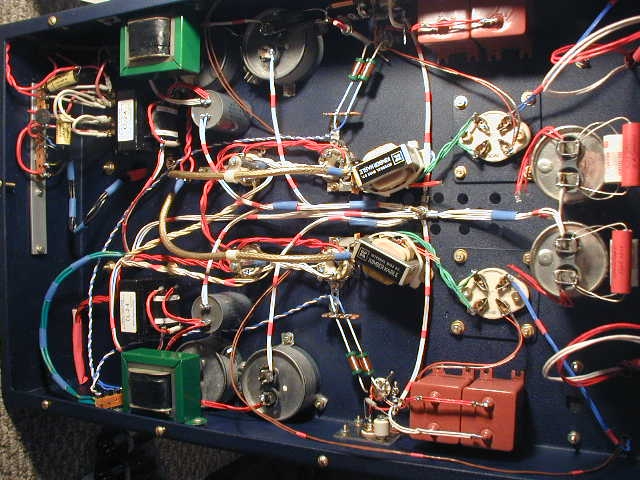

Here is a DIY amp design and build of mine from 28 months ago. This was when I was just starting on my journey of "high transfer efficiency" and it is filled with my learning errors.

Its FUN to build a 2A3 amplifier.... - drlowmu - Tube DIY Asylum

(1) The chassis is too large ( the amp was a stereo amp, a poor decision which created FAR too many

wire length compromises. (2) I should have done the 2A3s as monoblocks. (3) More recent builds have used more wire in parallel and shorter lengths, to get better overall results.

Dig that chassis, 12 gauge steel, laser cut, welded corners, and powder coated midnight blue wrinkle, one of my favorite finishes. Bare chassis by itself weighs 33 pounds, power transformer weighs another 18 pounds.

My newer 2013 amp is improved IMHO - as I learned more. The newest 2013 amplifier is also a two stage direct coupled circuit, ( for maximum possible transparency ), and designed with the Altec A7s in mind. Fun to hear on efficient speakers, almost a revelation.

LowOhms

Bookmarks